Calculating the True Cost of a Marine Repower: Your 2025 Budgeting Guide

The engine’s sticker price is just the beginning. Learn to budget for the entire project and avoid financial surprises.

Introduction

[Image: A boat owner looking thoughtfully at an old, rusty engine in a cramped engine room.]

Image Caption: The decision to repower starts with the engine, but a successful project depends on understanding the full financial picture.

So, your engine is on its last legs, and you’re considering a repower. You’ve seen the price of a new Yanmar or Volvo Penta and have a number in mind. But is that the real cost? In our decades of providing Marine Engine Repowering Solutions, we’ve found that the most successful projects are those where the owner understands one crucial fact: the engine itself is often only 40-60% of the total project cost.

A marine repower is a significant investment in your vessel’s future, its performance, and its value. This guide will walk you through every line item, both obvious and hidden, to ensure you can create a realistic budget and make an informed decision. Proper planning transforms a potentially stressful expense into a strategic and rewarding investment.

The True Cost Framework: The 4 Pillars of Repower Expense

Think of your total cost as a pyramid. The engine is the base, but without the layers on top, it’s just a piece of machinery sitting on the dock.

Pillar 1: The Core Components (The “Tip of the Iceberg”)

This is what most people budget for, but it’s more than just a single item.

-

The Engine Itself: The new or remanufactured diesel engine (e.g., a Yanmar 4LV250 or Vetus Deutz DTA67).

-

The Propulsion System: This is critical and often overlooked.

-

Gearbox/Transmission: Is it included with the engine? Often, yes, but verify.

-

Pod Drives: If you’re upgrading to a system like 【Volvo Penta IPS】, this is a major additional cost but comes with performance benefits.

-

Stern Gear: Will you reuse the existing propeller shaft, propeller, strut, and rudder? Often, these need to be replaced or refurbished to match the new engine’s power and RPM.

-

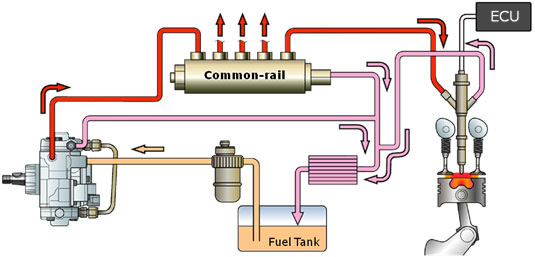

[Image: A simple pie chart showing the engine as 50% of total cost, labor 25%, and peripherals/other 25%.]

Image Caption: A typical repower cost breakdown. The engine is the largest single cost, but labor and peripheral components make up the other half.

Pillar 2: Labor & Professional Services (The “How It Gets Done”)

This is where budgets can unravel without a clear quote.

-

Professional Mechanical Labor: The cost for certified technicians to remove the old engine and install the new one. This includes engine alignment, which is a precision task.

-

Additional Trades: The project may require:

-

A Welder/Fabricator: To modify engine beds for the new footprint.

-

An Electrician: To integrate new control systems and gauges with your helm.

-

A Fiberglass Specialist: To repair or reinforce the engine room structure.

-

-

Project Management: A quality shop, like Wave Inboard Motors, will project-manage all these trades, ensuring a seamless process.

Pillar 3: Peripheral Systems & “While You’re In There” (The Hidden Costs)

The new engine will stress old supporting systems. This is the most common area for cost overruns.

-

Exhaust System: The new engine likely needs a new wet exhaust hose, muffler, and riser.

-

Fuel System: Old fuel lines, filters, and especially fuel tanks can contain debris or water that will destroy a new common-rail system. Replacing fuel tanks is a major, but often necessary, additional cost.

-

Cooling System: New raw-water intake hoses, seacocks, and strainers are highly recommended.

-

Electrical System: New battery cables, switches, and often new batteries are needed to handle the new engine’s demands.

-

Controls & Instrumentation: New electronic or mechanical control heads and gauges are typically required.

Pillar 4: The Intangible Costs (The “Value” Equation)

These don’t come with an invoice but dramatically impact your vessel’s worth.

-

Vessel Downtime: How long will the boat be out of commission? A professionally managed project minimizes this.

-

Resale Value: A modern, reliable repower with a transferable warranty significantly increases your boat’s market value and desirability.

-

Operational Savings: Factor in the money you’ll save on fuel with a more efficient engine and the money you’ll stop spending on constant repairs to the old one.

Interactive Cost Estimator Table

Use this table to build a rough estimate. Check the boxes that apply to your project.

| Cost Category | Budget Estimate | ✅ My Project Needs This |

|---|---|---|

| Engine & Gearbox | $25,000 – $60,000+ | ☐ |

| Labor (R&R, Alignment) | $5,000 – $15,000 | ☐ |

| Stern Gear (Shaft, Prop, Coupler) | $2,000 – $8,000 | ☐ |

| Exhaust System | $1,000 – $3,000 | ☐ |

| Fuel System (Lines, Filters, Tank) | $500 – $5,000+ | ☐ |

| Electrical (Cables, Batteries) | $1,000 – $4,000 | ☐ |

| Controls & Gauges | $1,500 – $4,000 | ☐ |

| Engine Bed Modifications | $1,000 – $5,000 | ☐ |

| Project Management | Included in Labor or 10-15% of Project | ☐ |

| **Potential Total Investment | $37,000 – $109,000+ |

Case Study: The “Budget” Repower vs. The “Turn-Key” Repower

[Image: Two side-by-side images. One shows a new engine installed in a clean, updated engine room. The other shows a new engine surrounded by old, worn-out hoses and wiring.]

Image Caption: A “Turn-Key” repower (left) addresses all peripheral systems, while a “Budget” repower (right) risks the new engine’s reliability by keeping old, failing components.

Let’s compare two approaches to repowering a 40-foot sportfish boat:

-

The “Budget” Approach: ($45,000)

-

Focuses only on Pillar 1.

-

New engine is installed, but old fuel hoses, 20-year-old fuel tank, and corroded shaft are reused.

-

Result: Six months later, debris from the old tank clogs a fuel injector, causing engine failure and requiring a $4,000 repair. The following year, the old shaft fails, requiring a $5,000 emergency haul-out and repair. Total Spent: $54,000 + significant downtime.

-

-

The “Turn-Key” Investment: ($65,000)

-

Addresses Pillars 1, 2, and 3 comprehensively.

-

Includes new engine, new fuel tank and lines, new exhaust, new shaft and propeller, and updated controls.

-

Result: The owner enjoys three years (and counting) of completely trouble-free operation, better performance, and a vessel that has increased in resale value by nearly the project’s cost.

-

This is the value of our professional Marine Engine Diagnostic Service—it identifies these peripheral risks before the project begins.

-

Frequently Asked Questions (FAQ)

Q1: What is the single most common hidden cost in a repower?

A: Fuel Tank Replacement. Old, corroded fuel tanks are a silent killer of new diesel engines. Inspecting and potentially replacing them is one of the most significant and most overlooked line items in a repower budget.

Q2: Can I save money by doing some of the work myself?

A: Yes, but with major caveats. An owner might handle the teardown of interior panels or old wiring. However, the core tasks—engine removal/installation, alignment, and fuel system plumbing—should be left to certified professionals to maintain the engine warranty and ensure safety and reliability.

Q3: How much does a typical marine repower cost?

A: For a mid-range diesel engine (150-300hp) in a 30-45 foot boat, a comprehensive, professional repower typically falls between $40,000 and $80,000. Smaller or larger engines and projects can range from $25,000 to well over $150,000.

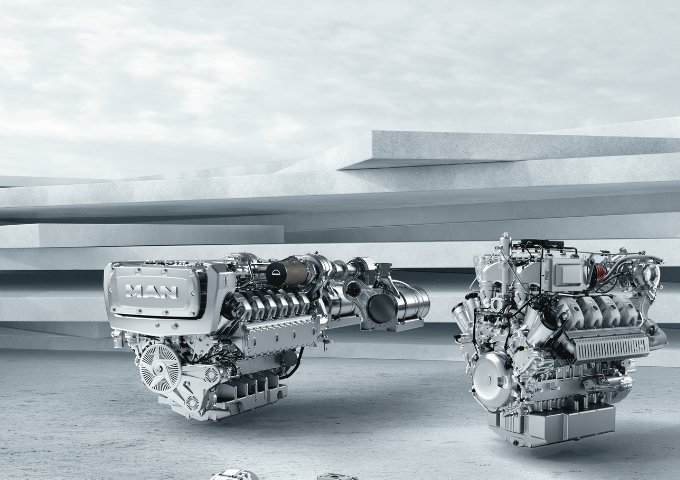

Q4: Is it cheaper to rebuild my current engine?

A: A rebuild can be 30-50% the cost of a full repower initially. However, it does not address the age and wear of all the peripheral systems, and you are still left with an outdated technology. A repower is a full-system renewal, while a rebuild is a major component repair. We explore this in Rebuild vs. Repower: Making the Right Choice for Your Boat.

Q5: How can I get an accurate quote for my project?

A: The only way to get a fixed-price quote is to have a professional survey of your vessel. Contact us to schedule a Marine Engine Diagnostic Service. We will provide a detailed, line-item quote that includes all necessary components and labor, so you know the true cost before you commit.

Conclusion: An Investment, Not an Expense

A marine repower is not just a repair; it’s a capital improvement that enhances your safety, enjoyment, and the vessel’s financial value. By understanding and budgeting for the true cost—the core engine, the labor, the peripherals, and the intangible value—you move from being a hopeful boat owner to an informed project manager.

Ready to move forward with confidence? The first step is a professional assessment. Contact Wave Inboard Motors for a comprehensive evaluation and a transparent, all-inclusive quote for your 【Marine Engine Repowering Solutions】. Let’s ensure your investment is sound from the first dollar to the final sea trial.