Heavy Displacement Trawler Engine Guide: Power, Torque, and Reliability

Matching the right diesel engine to your heavy-duty vessel for a decade of dependable service.

Introduction

The soul of a heavy displacement trawler—be it a Grand Banks, Krogen, or a rugged Nordic Tug—is defined by its steady, purposeful progress through the water. This character is dictated by its engine, a component where compromise is not an option. At Wave Inboard Motors, we’ve specialized in powering these iconic vessels for decades. Our expertise has taught us that selecting a heavy displacement trawler engine isn’t about finding the most horsepower; it’s about matching the engine’s fundamental characteristics—specifically its low-RPM torque and durability—to the hull’s immense load.

This guide cuts through the specifications to explain what truly matters for your heavy boat. We’ll explore why legacy workhorses like the <a href=”/vetus-deutz-dt4-70″ title=”Vetus Deutz DT4.70″>Vetus Deutz DT4.70</a> remain so revered and how modern engines from Yanmar and Beta Marine offer compelling advantages. Understanding this critical decision will ensure your trawler remains a safe, efficient, and comfortable home on the water for years to come.

The #1 Rule: Prioritize Torque Over Horsepower

For a heavy displacement hull, the ability to push through a headsea and maintain cruising speed under load is far more important than achieving a high top speed.

-

Torque is Turning Force: It’s the raw, twisting power that gets the propeller turning and keeps it turning against resistance.

-

Horsepower is a Calculation: HP is (Torque x RPM) / 5252. An engine can have high horsepower by revving high, but that’s inefficient for a displacement hull.

-

The Sweet Spot: A true heavy-duty marine engine produces its peak torque at low RPMs (often between 1800-2600 RPM). This is exactly where your trawler’s propeller will be most efficient, leading to better fuel economy, less strain, and a quieter ride.

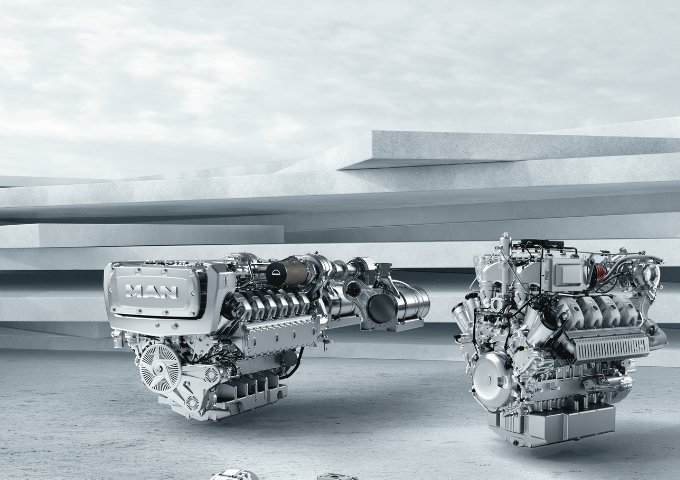

Engine Showdown: Legacy vs. Modern for Heavy Trawlers

The Legacy Workhorses: Built for a Lifetime

These engines, like the <a href=”/vetus-deutz-dt4-70″ title=”Vetus Deutz DT4.70″>Vetus Deutz DT4.70</a>, were designed from the ground up for industrial and marine durability.

Key Characteristics:

-

Low RPM Operation: Often rated at or below 3000 RPM, perfect for a large, slow-turning propeller.

-

Massive Internal Components: Heavy-duty crankshafts, large bore and stroke, and robust bearing surfaces designed for a 20,000+ hour service life.

-

Simplified Systems: Many, like the air-cooled Deutz, eliminate complex seawater cooling circuits entirely.

-

Ideal For: Purists, long-range passagemakers, and owners of classic trawlers where original character and ultimate mechanical simplicity are paramount.

The Modern Marvels: Efficiency and Comfort

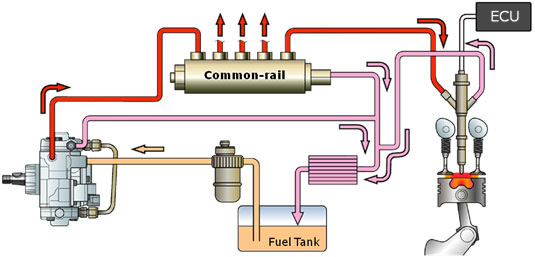

Modern engines are based on high-speed industrial blocks (e.g., Kubota) that are heavily de-rated and engineered for marine use.

Key Characteristics:

-

Advanced Fuel Injection: Results in superior fuel efficiency and cleaner emissions.

-

Freshwater Cooling Systems: Standard equipment that dramatically extends engine life by preventing internal corrosion.

-

Refined Operation: Significant reductions in noise and vibration through advanced balancing and sound-shielding.

-

Ideal For: The majority of cruisers and liveaboards who value a quiet cockpit, modern warranty support, and the best possible fuel range.

Matching Your Trawler to an Engine: A Practical Guide

| Trawler Size (Length/Displacement) | Legacy Engine Example | Modern Engine Equivalent | Key Consideration |

|---|---|---|---|

| 32-38 ft / 15,000-22,000 lbs | Vetus Deutz DT4.70 (68hp) | Yanmar 4JH4-TE (110hp) | Modern engines offer more power in a lighter package; legacy engines provide brute-force simplicity. |

| 38-42 ft / 22,000-30,000 lbs | Lehman 120 (120hp) | Beta Marine 115 (115hp) | This is a classic repower range. A <a href=”/trawler-repowering-guide” title=”Trawler Repowering Guide”>trawler repower</a> here dramatically improves performance. |

| 42-48 ft / 30,000-45,000 lbs | Lugger L-6140A (140hp) | Cummins QSB5.9 (220hp) | Focus on massive low-end torque and robust <a href=”/drivetrain-stern-gear” title=”Drivetrain and Stern Gear”>stern gear</a> to handle the power. |

Our Expert Take: While we hold a deep respect for the legacy engines that built the trawler legacy, our professional recommendation for most owners leans toward a modern, freshwater-cooled diesel. The benefits in daily comfort, fuel efficiency, and the security of a factory warranty are transformative. However, for a vessel whose original design was centered around a specific legacy engine, a professional <a href=”/marine-diesel-overhaul” title=”Marine Diesel Overhaul”>overhaul or rebuild</a> can sometimes be the most authentic and cost-effective path.

Critical Installation Factors for Heavy Boats

Putting a new engine in a heavy trawler isn’t like any other installation. The forces involved are immense.

-

Engine Bed Integrity: The wooden or steel engine beds must be inspected and often reinforced to handle the torque and weight of the new powerplant. This is a non-negotiable part of our <a href=”/marine-engine-survey” title=”Marine Engine Survey”>marine engine survey</a> process.

-

Propulsion System Alignment: This is the single most critical step post-installation. A perfect <a href=”/propulsion-system-alignment” title=”Propulsion System Alignment”>marine propulsion system alignment</a> ensures the engine’s power is efficiently transferred to the propeller, preventing vibration and premature wear on the shaft, strut, and cutless bearing.

-

Stern Gear Matching: The propeller shaft, propeller, and rudder must be matched to the new engine’s power and RPM. An incorrectly sized propeller will make even the most powerful engine feel anemic.

Frequently Asked Questions (FAQ)

Q1: My old Lehman/Deutz/Perkins runs fine. Why should I consider a repower?

A: Reliability is more than just an engine that starts. Modern engines offer reliability plus significant gains in safety (fewer fumes, better electrical systems), comfort (less noise/vibration), and efficiency (more miles per gallon). A <a href=”/trawler-repowering-guide” title=”Trawler Repowering Guide”>repower</a> is an investment in your quality of life on the water.

Q2: Is an air-cooled engine like the Deutz a good choice for a liveaboard?

A: It depends on your priorities. The <a href=”/vetus-deutz-dt4-70″ title=”Vetus Deutz DT4.70″>Vetus Deutz DT4.70</a> is phenomenally reliable and simple, but it is significantly louder and produces more heat in the engine room than a water-cooled equivalent. For many liveaboards, the trade-off in comfort is too great.

Q3: How important is a keel cooler?

A: For a heavy displacement trawler that may see extended cruising in muddy or debris-filled waters, a keel cooler is a superb option. It completely separates the engine’s cooling system from the raw, corrosive seawater, enhancing longevity and reliability. Many modern repower packages can be fitted with one.

Q4: What’s the most common mistake in a trawler repower?

A: Under-propping or over-propping the vessel. Installing the wrong propeller is like putting the wrong gears in a truck—it kills performance and efficiency. This is why a holistic approach that includes a <a href=”/marine-engine-installation” title=”Marine Engine Installation”>professional installation</a> and system analysis is crucial.

Conclusion: The Right Heart for Your Hull

Choosing the right heavy displacement trawler engine is a balance of engineering, personal cruising style, and long-term goals. Whether you are drawn to the timeless, mechanical purity of a legacy engine or the refined, efficient power of a modern diesel, the key is to make an informed decision based on torque, reliability, and a professional installation.

Ready to discuss the perfect engine for your trawler? Contact the experts at Wave Inboard Motors for a consultation. We’ll help you navigate the options to find the ideal powerplant for your next adventure.