Understanding Modern Common Rail Diesel Systems: The Tech Behind the Power

How high-pressure precision injection creates cleaner, more powerful, and more efficient marine engines.

Introduction

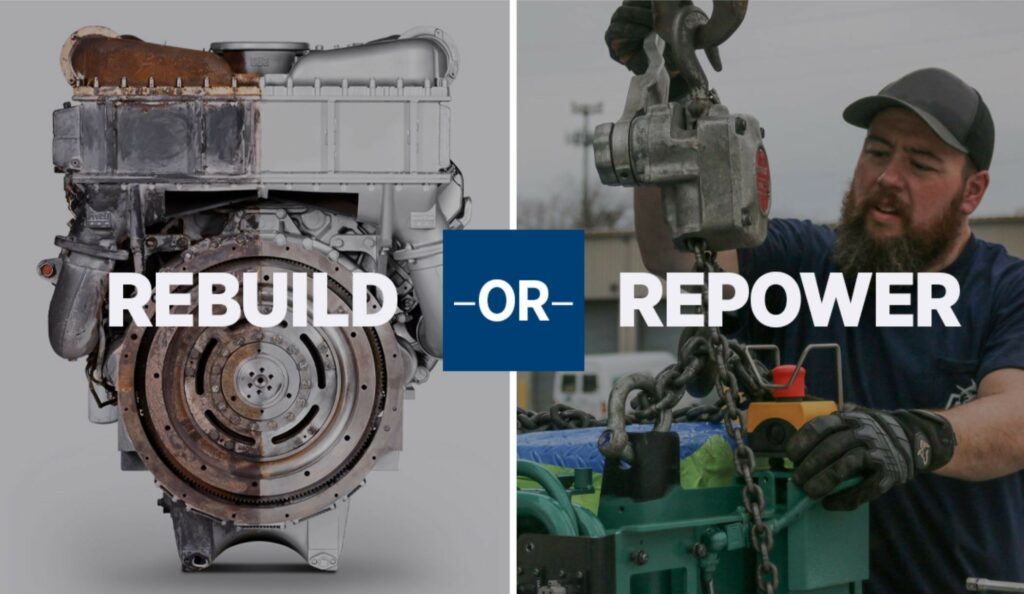

[Image: A sleek, modern marine diesel engine like a Yanmar 4LV or Volvo Penta D4, with a focus on the common rail and injectors.]

Image Caption: Modern common rail diesel engines are quieter, smoother, and more powerful than their predecessors, all thanks to revolutionary fuel injection technology.

For decades, marine diesel engines were defined by their distinctive clatter and smoky exhaust. While reliable, they were not known for refinement. That all changed with the advent of the Common Rail Diesel (CRDi) system. This technology represents the single most significant leap in diesel engine performance and efficiency in the last 50 years.

At Wave Inboard Motors, our expertise isn’t just in installing engines; it’s in understanding the complex systems within them. Through our Marine Engine Diagnostic Service, we’ve seen firsthand how common rail technology has revolutionized onboard power, offering boat owners unprecedented levels of performance and reliability. This guide will demystify the common rail system, showing you how it works and why it matters for your vessel.

What is a Common Rail Diesel System?

In simple terms, a common rail system is a high-pressure fuel storage and delivery system that feeds fuel to the engine’s injectors. Unlike older systems where fuel pressure was generated by each injector pump individually, common rail separates the pressure generation from the injection event.

Think of it like a municipal water system versus a well with a hand pump:

-

Old System (Injection Pump): You have to pump hard (generate pressure) each time you want a glass of water (injection event). The pressure is inconsistent.

-

Common Rail System (City Water): High pressure is constantly maintained in the main water line (“common rail”). You simply turn a tap (the injector) to get a precise, high-pressure stream whenever you want.

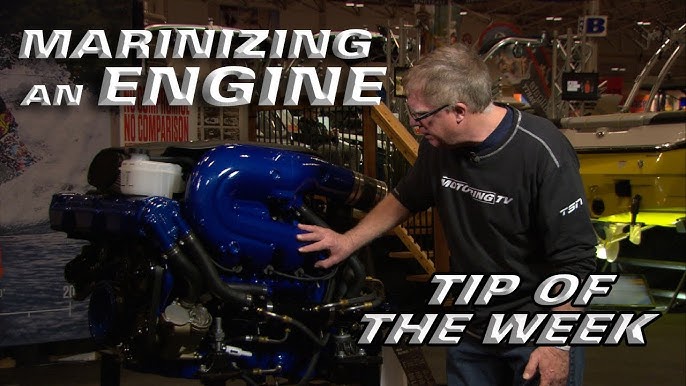

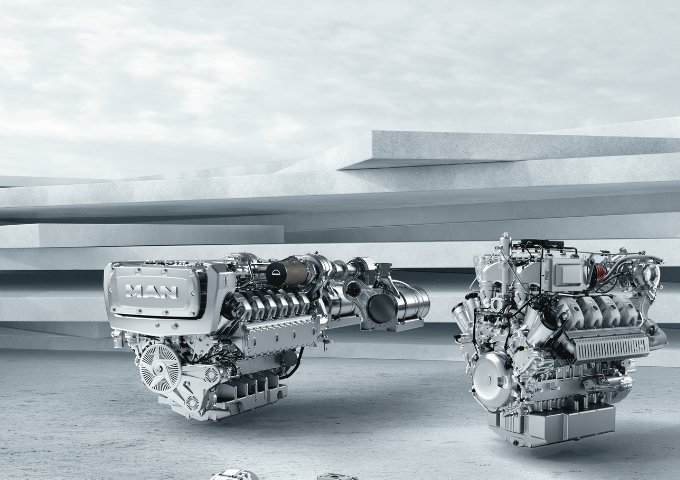

[Image: A clear, color-coded diagram of a common rail system showing the fuel tank, lift pump, high-pressure pump, common rail (accumulator), and electronic injectors connected to an ECU.)

Image Caption: A common rail system features a central high-pressure fuel reservoir (the rail) that supplies all injectors, all controlled by a sophisticated Engine Control Unit (ECU).

How It Works: The 5 Key Components

-

High-Pressure Fuel Pump: This is the heart of the system. It’s a mechanically driven pump that pressurizes fuel to extremely high levels—often over 30,000 PSI (2,000+ bar)—and sends it to the rail.

-

Common Rail (Fuel Accumulator): This is a thick-walled, tubular reservoir that runs along the top of the engine. Its job is to store the high-pressure fuel and dampen the pulses from the pump, maintaining a constant, stable pressure for all injectors.

-

Electronic Injectors: These are the precision valves, controlled by the Engine Control Unit (ECU). They open and close in milliseconds to deliver fuel into the combustion chamber. Their speed and precision are what make common rail so effective.

-

Engine Control Unit (ECU): The brain of the operation. The ECU uses data from sensors all over the engine (crank position, cam position, boost pressure, rail pressure, etc.) to calculate the perfect moment and duration for injection.

-

Sensors: A network of sensors provides real-time data to the ECU, allowing it to make instantaneous adjustments for optimal performance and emissions control.

The Revolutionary Benefits for Marine Use

1. More Power & Torque

By allowing for extremely high injection pressures, the fuel is atomized into a much finer mist. This creates a more complete and efficient burn, extracting more power from every drop of fuel. Common rail engines produce significantly more torque, especially at lower RPMs, which is ideal for getting a heavy boat on plane or pushing through a head sea.

2. Superior Fuel Efficiency

The ECU can perform multiple, precise injection events per combustion cycle.

-

Pilot Injection: A tiny amount of fuel is injected first to gently begin combustion, reducing the “clatter” and pressure spike.

-

Main Injection: The primary charge of fuel is delivered for power.

-

Post Injection: A final small injection can help burn off soot and reduce emissions.

This level of control translates directly into better fuel economy.

3. Dramatically Reduced Noise & Vibration

The pilot injection is the key to a quieter diesel engine. By softening the initial combustion shock, it eliminates the classic diesel knock. The result is a smoother, quieter engine that makes conversation in the cockpit and salon much more pleasant.

4. Lower Emissions

A cleaner, more complete burn means fewer unburned hydrocarbons and particulate matter (soot) are released into the atmosphere. This technology is the primary reason modern marine diesels can comply with stringent EPA and IMO emissions standards.

[Image: A side-by-side comparison chart of Power, Fuel Efficiency, Noise, and Emissions, showing Common Rail Diesel outperforming Older Mechanical Diesel in all four categories.]

Image Caption: The tangible benefits of common rail technology are clear across every performance metric that matters to a boat owner.

Common Rail vs. Older Mechanical Injection

| Feature | Common Rail Diesel | Mechanical Injection Diesel |

|---|---|---|

| Injection Pressure | Very High (30,000+ PSI), Constant | Lower, Varies with RPM |

| Injection Control | Fully Electronic, Precise | Mechanical, Limited Precision |

| Noise & Vibration | Quiet & Smooth | Noisy & Pronounced Vibration |

| Fuel Efficiency | Excellent | Good |

| Power & Torque | High, Broad Torque Curve | Lower, Narrower Curve |

| Emissions | Very Low | Higher |

| Complexity | High (Requires Expert Diagnosis) | Low (Easier to Field-Service) |

Essential Maintenance & Potential Concerns

The sophistication of common rail systems demands a higher level of care. The components are precision-made to tolerances finer than a human hair, making them vulnerable to poor fuel quality.

-

Fuel Quality is Non-Negotiable: Water, dirt, and algae in the fuel will destroy a common rail system. The high-pressure pump and injectors are lubricated by the fuel itself. Contaminants act like sandpaper, causing catastrophic and expensive failures.

-

Expert Service Required: Diagnosing and servicing these systems requires specialized tools, software, and training. This is not a system for the casual DIY mechanic. Our 【Scheduled Marine Diesel Maintenance】 program is specifically designed to protect this investment.

-

The Importance of Filtration: Using high-quality, OEM-rated fuel filter/water separators and changing them at recommended intervals is the single most important thing you can do to protect your engine.

[Image: A close-up photo of a damaged fuel injector tip next to a new one, highlighting the erosion caused by contaminated fuel.]

Image Caption: A single tank of bad fuel can cause thousands of dollars in damage to the high-pressure fuel pump and injectors, underscoring the critical need for pristine fuel and quality filtration.

Frequently Asked Questions (FAQ)

Q1: Are common rail diesel engines reliable?

A: Yes, they are incredibly reliable when properly maintained. Their primary vulnerability is fuel quality. With clean fuel and regular professional maintenance, a common rail engine can provide thousands of trouble-free hours.

Q2: What are the signs of a failing common rail system?

A: Symptoms include hard starting, loss of power, rough idle, excessive black or white smoke, and a knocking sound from the fuel system. If you experience any of these, seek a 【Marine Engine Diagnostic Service】 immediately to prevent further damage.

Q3: Can I use biodiesel in my common rail marine engine?

A: You must consult your engine manufacturer’s guidelines. While some newer engines can handle certain blends (like B10 or B20), many do not approve it due to concerns about fuel stability, deposits, and potential damage to seals and components.

Q4: Is a common rail engine a good choice for a repower?

A: Absolutely. The benefits in fuel efficiency, smoothness, and power make a modern common rail diesel an excellent choice for a 【Marine Engine Repowering Project】. You’ll enjoy a quieter ride, lower fuel bills, and more responsive power.

Q5: Why is common rail repair so expensive?

A: The components are precision-engineered and manufactured to withstand immense pressures. The high-pressure pump and injectors are complex and costly to produce or remanufacture. This underscores the importance of preventative maintenance and using a qualified technician.

Conclusion: Precision Power for the Modern Mariner

The common rail diesel system is a masterpiece of engineering that has transformed the boating experience. It delivers the power and torque we need with the efficiency and refinement we desire. While it demands respect and proper care, the performance benefits are undeniable.

Protect your investment. Whether you’re considering a new 【Yanmar Marine Engines】 or 【Volvo Penta Marine Engines】 with common rail technology, or you need to maintain your existing system, trust the experts at Wave Inboard Motors. We have the tools, training, and experience to keep your high-performance diesel running flawlessly.