Understanding Marine Engine Marinization: The Complete Guide

How industrial diesel engines are transformed into reliable marine power plants.

Introduction

[Image: Side-by-side comparison showing an industrial engine and its marine-converted counterpart]

Image Caption: Marine marinization transforms reliable industrial engines into specialized marine power plants capable of withstanding the harsh marine environment.

Marine engine marinization is the sophisticated process of converting industrial or automotive diesel engines for reliable marine operation. This complex transformation involves much more than simply bolting on a marine transmission—it requires comprehensive re-engineering to ensure the engine can withstand the unique challenges of the marine environment. At Wave Inboard Motors, our 15 years of experience with 【Marine Engine Installation Services】 has given us deep insight into what separates properly marinized engines from problematic conversions.

The marinization process addresses critical factors including corrosion protection, cooling system redesign, different operating profiles, and safety requirements that simply don’t exist in land-based applications. Understanding this process helps boat owners appreciate why a properly marinized engine like the 【Vetus VH4.65】 outperforms and outlasts simple industrial conversions.

The Core Marinization Process

1. Base Engine Selection

-

Industrial Heritage: Choosing proven reliable blocks (Mitsubishi, Kubota, Yamnar)

-

Marine Suitability: Assessing RPM range, torque curve, and durability

-

Parts Availability: Ensuring global support network

-

Serviceability: Evaluating maintenance access and simplicity

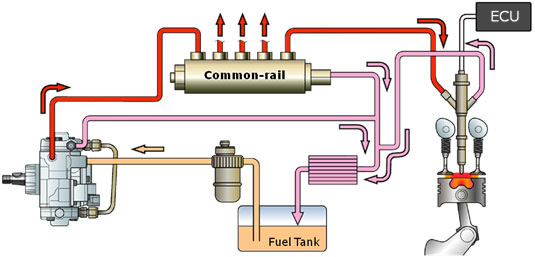

2. Cooling System Transformation

-

Raw Water Cooling: Direct seawater cooling (simple but corrosive)

-

Heat Exchanger System: Closed-loop freshwater cooling with seawater heat rejection

-

Keel Cooling: Hull-mounted cooling without seawater intake

-

Component Protection: Marine-grade materials throughout system

3. Corrosion Protection System

-

Cathodic Protection: Sacrificial zinc anodes

-

Material Upgrades: Stainless steel, bronze, and marine alloys

-

Coatings & Finishes: Saltwater-resistant paints and treatments

-

Electrical Isolation: Preventing galvanic corrosion

Critical Marinization Components

Heat Exchanger System

-

Materials: Copper-nickel alloys or titanium

-

Design: Compact, efficient heat transfer

-

Maintenance: Regular cleaning and inspection required

Marine Transmission

-

Function: Connects engine to propeller shaft

-

Types: Direct drive, reduction gear, V-drive

-

Features: Hydraulic or mechanical operation

-

Cooling: Integrated heat exchanger

Marine Exhaust System

-

Water-Injected: Cooled exhaust gases

-

Dry Stack: High-temperature systems

-

Materials: Fiberglass, stainless steel, special alloys

-

Safety: Prevents water backflow into engine

Electrical System Marineization

-

Waterproof Connectors: IP67 or better ratings

-

Marine-Grade Wiring: Tinned copper conductors

-

Alternator Upgrades: Saltwater-protected units

-

Shielding: Protection from moisture and corrosion

Marinization Standards & Certification

Key Standards

-

ABYC (American Boat and Yacht Council)

-

ISO 8846 (Marine electrical requirements)

-

USCG (United States Coast Guard)

-

CE Certification (European compliance)

Certification Requirements

-

Fuel System Safety: Leak prevention and containment

-

Electrical Safety: Ignition protection and grounding

-

Emissions Compliance: IMO Tier standards

-

Noise Regulations: dB level limitations

Professional vs. DIY Marinization

| Aspect | Professional Marinization | DIY Conversion |

|---|---|---|

| Safety | Certified, tested systems | Unknown reliability |

| Performance | Optimized for marine use | Compromised performance |

| Warranty | Comprehensive coverage | No warranty |

| Resale Value | Full value retention | Significant reduction |

| Insurance | Easily insured | Often rejected |

Marinization Case Studies

Vetus Marinization Process

-

Base Engine: Mitsubishi industrial block

-

Cooling: Freshwater heat exchanger system

-

Transmission: Marine gear with various ratios

-

Controls: Marine-specific instrument panel

-

Result: 【Vetus VH4.65】 – reliable marine power

Beta Marine Approach

-

Base Engine: Kubota industrial

-

Cooling: Keel cooling options available

-

Installation: Sailboat-focused packaging

-

Support: Global service network

Maintenance Considerations for Marinized Engines

Critical Maintenance Points

-

Heat Exchanger: Regular cleaning and inspection

-

Raw Water Pump: Impeller replacement intervals

-

Corrosion Protection: Anode inspection and replacement

-

Exhaust System: Regular inspection for leaks

Professional Maintenance

-

【Scheduled Marine Diesel Maintenance】 programs

-

Corrosion monitoring and prevention

-

System performance verification

-

Safety system checks

Frequently Asked Questions (FAQ)

Q1: Can any diesel engine be marinized?

A: While technically possible, successful marinization requires starting with a suitable base engine that has the right characteristics for marine use, including appropriate RPM range, torque curve, and serviceability.

Q2: How much does professional marinization cost?

A: Quality marinization typically adds $5,000-$15,000 to the base engine cost, depending on the complexity and components required. This investment ensures reliability and safety.

Q3: What’s the difference between marine and industrial cooling systems?

A: Marine systems must handle saltwater corrosion, biological growth, and continuous operation at varying loads. Industrial systems are designed for cleaner water and more consistent operation.

Q4: How long does the marinization process take?

A: Professional marinization of a proven design typically takes 4-8 weeks from base engine to finished marine power plant, including testing and certification.

Q5: Are marinized engines as reliable as purpose-built marine engines?

A: Properly marinized engines using quality components and professional engineering can be equally reliable, often benefiting from the proven reliability of their industrial base engines.

Q6: What about emissions compliance for marinized engines?

A: Professional marinizers ensure their products meet applicable marine emissions standards (IMO Tier I, II, or III depending on engine size and application).

Q7: Can I marinize an engine myself to save money?

A: While possible, DIY marinization is generally not recommended due to safety concerns, insurance issues, and the high likelihood of creating an unreliable power plant. Professional 【Marine Engine Installation Services】 ensure proper results.

Q8: How do I verify a marinizer’s quality?

A: Look for:

-

Industry certifications (ABYC, ISO)

-

Established track record

-

Comprehensive warranty

-

Professional 【Marine Engine Diagnostic Service】 capabilities

Q9: What are the most common marinization failures?

A: Typical issues include:

-

Inadequate corrosion protection

-

Poor heat exchanger design

-

Incorrect transmission matching

-

Substandard electrical components

Q10: Can marinized engines be used in commercial applications?

A: Yes, many commercial vessels use properly marinized engines. However, they must meet additional regulatory requirements and typically undergo more rigorous certification.

The Future of Marine Marinization

Emerging Trends

-

Hybrid Systems: Integration with electric propulsion

-

Advanced Emissions Control: SCR and DPF systems

-

Digital Integration: Smart monitoring and control systems

-

Alternative Fuels: Compatibility with biofuels and synthetics

Technology Advancements

-

Better Materials: Advanced composites and alloys

-

Improved Efficiency: Optimized for specific marine duty cycles

-

Enhanced Monitoring: Real-time system health assessment

-

Modular Design: Easier service and component replacement

Conclusion: The Value of Professional Marinization

Quality marinization transforms reliable industrial engines into specialized marine power plants capable of withstanding the unique demands of marine operation. The process involves much more than simple component swapping—it requires comprehensive engineering, quality materials, and thorough testing.

When considering 【Marine Engine Repowering Solutions】, understanding the marinization process helps you appreciate why professional conversions from reputable manufacturers provide better long-term value and reliability than cheap alternatives or DIY attempts.

Need expert advice on marine power plants? Contact Wave Inboard Motors for professional 【Marine Engine Diagnostic Service】 and guidance on selecting properly marinized engines for your vessel.

Authority-Building Internal Links

Link to Services:

-

Professional 【Marine Engine Installation Services】

-

Explore our 【Marine Engine Repowering Solutions】

-

Maintain reliability with 【Scheduled Marine Diesel Maintenance】

-

Trust our 【Marine Engine Diagnostic Service】

Link to Information:

-

Learn about 【Understanding Common Rail Diesel Systems】

-

Compare options in 【Sailboat Engine Selection Guide】

-

Read our 【Vetus Engine Packaging Benefits】

-

Calculate costs with 【Calculating the True Cost of a Marine Repower】