Volvo Penta DPI Turbo Technology: The Complete Guide

How Dual Pressure Intake turbocharging revolutionizes marine engine performance and efficiency

Introduction

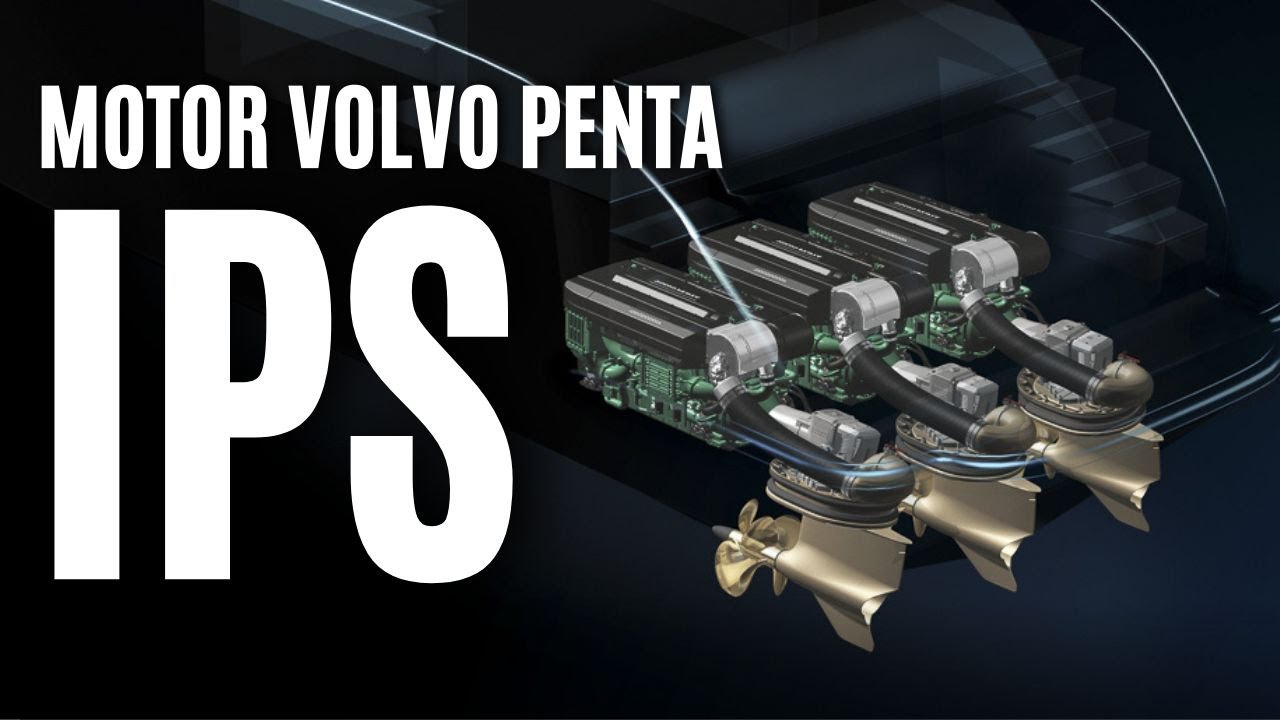

[Image: Detailed cutaway diagram of a DPI turbo system showing dual intake paths]

Image Caption: Volvo Penta’s DPI turbo system uses innovative dual-path intake technology to deliver exceptional performance across the entire RPM range.

Volvo Penta DPI (Dual Pressure Intake) Turbo Technology represents a significant leap forward in marine diesel engine performance. This advanced turbocharging system addresses the fundamental challenge of traditional turbochargers: the trade-off between low-RPM response and high-RPM power. At Wave Inboard Motors, our extensive experience with 【Marine Engine Installation Services】 for DPI-equipped engines has shown us firsthand how this technology transforms vessel performance.

Unlike conventional single-stage turbochargers that suffer from “turbo lag” at low engine speeds, the DPI system provides immediate throttle response while maintaining strong top-end power. This guide explores the engineering behind DPI technology, its real-world benefits, and why it’s become the gold standard for modern marine propulsion systems like the 【Volvo Penta D6 Series】.

How DPI Turbo Technology Works

The Traditional Turbocharger Limitation

Traditional single-stage turbochargers face a fundamental physics problem:

-

Low RPM: Exhaust gas flow is insufficient to spin the turbo quickly, causing “turbo lag”

-

High RPM: Excessive exhaust gas flow can overspeed the turbo, requiring wastegates

-

Compromise: Engineers must choose between low-end response or high-end power

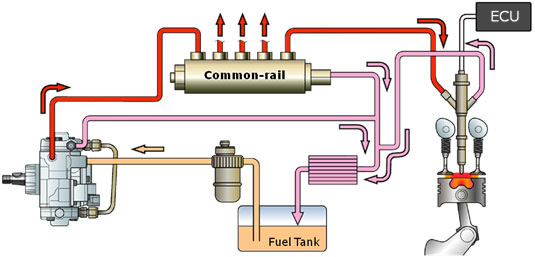

The DPI Solution: Dual-Path Intelligence

Volvo Penta’s DPI system solves this through an intelligent dual-path approach:

1. Low-RPM Operation

-

Path: Air takes longer route through both turbine chambers

-

Result: Increased gas velocity for faster turbo spool-up

-

Benefit: Eliminates turbo lag, provides immediate power

2. High-RPM Operation

-

Path: Secondary valve opens, creating shorter air path

-

Result: Reduced backpressure, increased airflow

-

Benefit: Maintains peak power output efficiently

[Image: Flow diagram comparing low-RPM and high-RPM air paths]

Image Caption: The DPI system’s intelligent air routing adapts to engine demands in real-time for optimal performance at any speed.

DPI vs Traditional Turbocharging: Performance Comparison

| Performance Aspect | DPI Turbo System | Traditional Single Turbo | Competitor Twin-Turbo |

|---|---|---|---|

| Low-RPM Response | Instantaneous | Laggy, delayed | Good, but complex |

| Power Band Width | Extremely Broad | Narrow peaky band | Broad, but with complexity |

| Fuel Efficiency | 15-20% Better | Standard | Moderate improvement |

| System Complexity | Moderate | Simple | High (multiple turbos) |

| Maintenance | Straightforward | Simple | Complex, more components |

Real-World Benefits for Boat Owners

1. Transformational Acceleration

-

0-20 knots: Up to 30% faster acceleration

-

Planning time: Significant reduction in time-to-plane

-

Load carrying: Maintains performance with heavy loads

-

Sea conditions: Better performance in rough water

2. Exceptional Fuel Efficiency

-

Cruising efficiency: 15-20% improvement at typical operating speeds

-

Optimal combustion: Precise air-fuel ratio across all RPMs

-

Reduced emissions: Cleaner burn meets strictest regulations

-

Long-range capability: Extended cruising range

3. Enhanced Vessel Control

-

Docking precision: Immediate power when needed

-

Following seas: Quick response to changing conditions

-

Maneuverability: Superior control in tight quarters

-

Safety: Predictable power delivery in emergencies

DPI Technology in Volvo Penta Engine Series

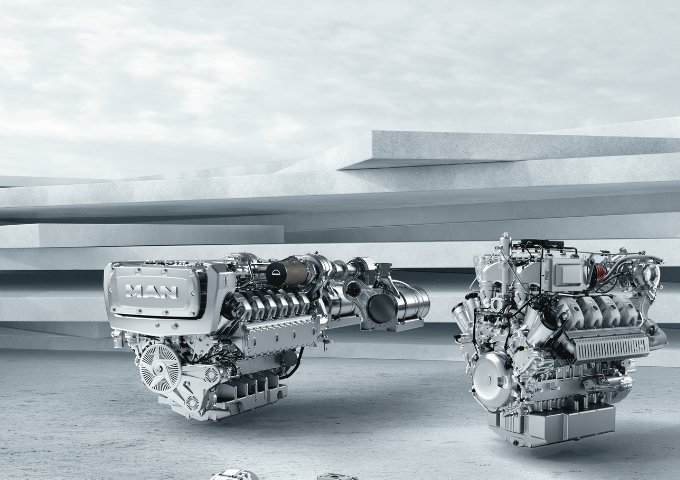

D4 Series (175-300 hp)

-

Applications: Mid-size cruisers, sportfish boats

-

Benefits: Class-leading efficiency in compact package

-

Perfect for: 【Volvo Penta IPS350】 systems

D6 Series (330-480 hp)

-

Applications: Luxury yachts, performance vessels

-

Benefits: Exceptional torque for heavy vessels

-

Perfect for: 【Volvo Penta IPS450】 and 【IPS600】 systems

D8 Series (550-600 hp)

-

Applications: Large yachts, commercial vessels

-

Benefits: Massive power with refined operation

-

Perfect for: Heavy displacement and high-speed craft

Maintenance & Service Considerations

Routine Maintenance Requirements

-

Air filter service: Regular inspection and replacement

-

Boost pressure checks: Verify system operation

-

Electronic controls: EVC system diagnostics

-

Professional 【Scheduled Marine Diesel Maintenance】

Common Service Intervals

-

Every 250 hours: Air filter inspection

-

Every 500 hours: Full system diagnostics

-

Annual: Boost pressure verification

-

1000 hours: Comprehensive turbo system check

Professional Service Importance

-

Specialized tools required for calibration

-

Volvo Penta EVC software for system diagnostics

-

Certified technicians with DPI-specific training

-

Genuine Volvo Penta parts for optimal performance

Frequently Asked Questions (FAQ)

Q1: How does DPI technology differ from traditional twin-turbo systems?

A: While both address turbo lag, DPI uses a single turbo with dual intake paths rather than multiple turbos. This provides similar benefits with less complexity, weight, and maintenance requirements.

Q2: What is the expected service life of a DPI turbo system?

A: With proper maintenance, DPI turbo systems typically last 8,000-10,000 hours. Regular 【Scheduled Marine Diesel Maintenance】 is crucial for achieving maximum service life.

Q3: Can DPI technology be retrofitted to older Volvo Penta engines?

A: No, DPI is an integrated system requiring specific engine architecture, electronics, and cooling systems. It’s only available on newer D4, D6, and D8 series engines.

Q4: How does DPI affect engine reliability?

A: DPI enhances reliability by reducing thermal stress through optimized combustion and eliminating the rapid spool-up/down cycles that damage traditional turbos.

Q5: What fuel quality is required for DPI engines?

A: DPI systems require clean, high-quality diesel fuel. Contaminated fuel can damage the precise injection and turbo systems. Regular fuel filter maintenance is essential.

Q6: How does DPI technology work with Volvo Penta’s IPS systems?

A: DPI is perfectly matched with IPS pod drives. The immediate low-end torque complements the IPS efficiency, creating an exceptionally responsive and efficient propulsion package.

Q7: What warranty coverage applies to DPI turbo systems?

A: DPI components are covered under Volvo Penta’s standard 5-year factory warranty when installed and maintained by authorized dealers.

Q8: How does DPI performance change at high altitudes?

A: DPI systems maintain better performance at altitude than conventional turbos due to their adaptive airflow management, though some power reduction still occurs.

Q9: Can I hear or feel the DPI system operating?

A: The transition between intake paths is seamless and undetectable to operators. The only noticeable effect is the instant throttle response and smooth power delivery.

Q10: What training is required to service DPI systems?

A: DPI systems require Volvo Penta certified technicians with specific training on the system’s unique architecture and diagnostic procedures.

Technical Specifications & Performance Data

DPI System Components

-

Turbocharger: High-efficiency ball bearing turbo

-

Intake manifold: Dual-path design with electronic controls

-

Wastegate: Precision electronic wastegate control

-

Sensors: Multiple pressure and temperature sensors

-

ECU: Integrated engine control unit

Performance Metrics

-

Boost response: 0.8 seconds from idle to full boost

-

Maximum boost pressure: 25-35 psi (engine dependent)

-

Operating temperature range: -40°C to 120°C

-

Design life: 10,000+ hours

Conclusion: Why DPI Matters for Modern Boating

Volvo Penta’s DPI Turbo Technology represents more than just an incremental improvement—it’s a fundamental shift in how marine diesels deliver power. By solving the ancient turbocharger compromise between low-end response and high-end power, DPI technology provides:

-

Safety through predictable, immediate power

-

Efficiency through optimized combustion

-

Performance that transforms the boating experience

-

Reliability through reduced thermal stress

For vessel owners considering new installations or 【Marine Engine Repowering Solutions】, DPI-equipped engines offer a compelling combination of performance and efficiency that simply wasn’t possible with previous generations of marine diesel technology.

Ready to experience DPI performance? Contact Wave Inboard Motors to learn how DPI technology can transform your vessel’s performance and efficiency.

Authority-Building Internal Links

Link to Services:

-

Professional 【Marine Engine Installation Services】 for DPI engines

-

Explore our 【Marine Engine Repowering Solutions】

-

Maintain reliability with 【Scheduled Marine Diesel Maintenance】

-

Trust our 【Marine Engine Diagnostic Service】

Link to Information:

-

Learn more about 【Volvo Penta IPS Pod Drives】

-

Compare options in 【Twin Engine Marine Applications Guide】

-

Read our analysis 【Benefits of Volvo Penta IPS Pod Drives】

-

Calculate your project with 【Calculating the True Cost of a Marine Repower】